CIVIL WORKS GUIDELINES FOR MICRO-HYDROPOWER IN NEPAL

133

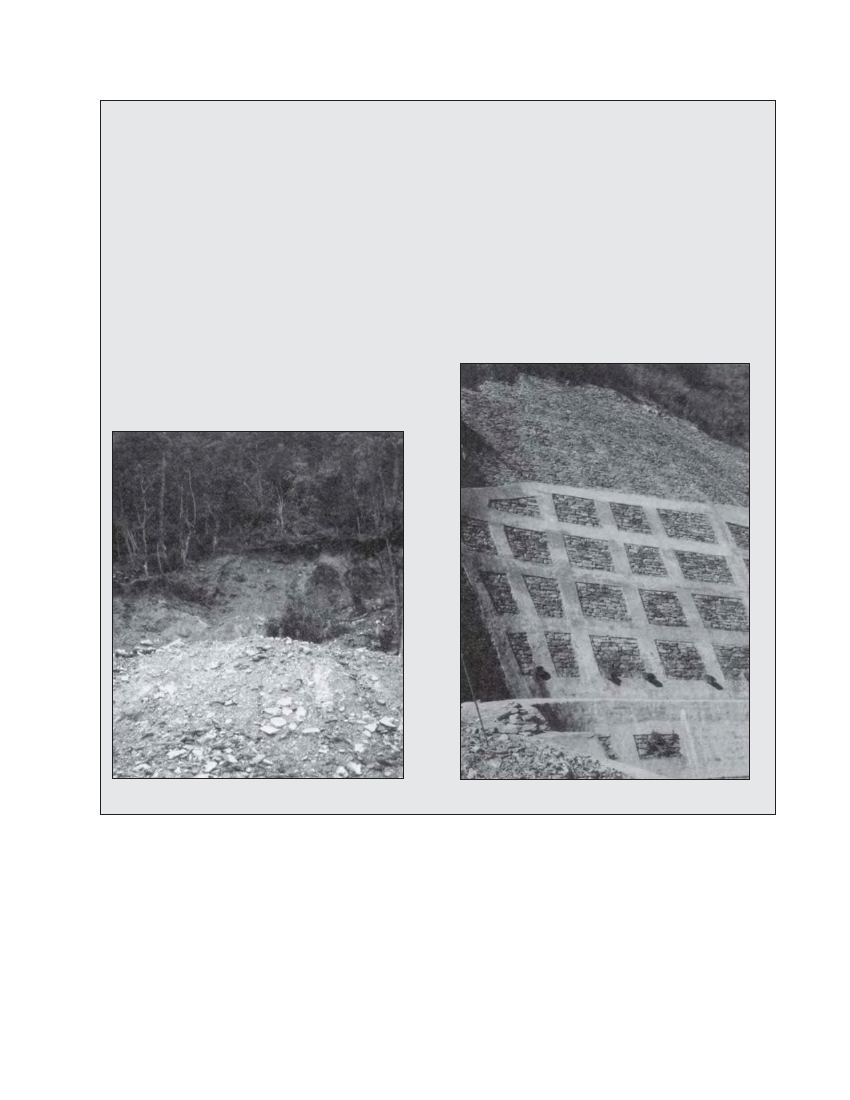

Box 9.1 Use of masonry grid to stabilise the jhankre mini-hydro powerhouse area slope

In order to increase the gross head of the Jhankre mini-hydro scheme, it was decided to excavate a 20 m depth at the power-house

area. This required stabilising the hill slope behind the powerhouse area. This area also had to drain ground water due to seepage

from the cultivated terraces (paddy fields) above. When irrigation water was provided for the paddy fields significant seepage was

observed at the powerhouse area. After considering various alternatives, it was decided to use a grid of masonry beams and

columns infilled with dry stone panels. Photographs 9.5 and 9.6 show the hillside during excavation and after the construction of the

masonry grid.

The hill slopes were first excavated at 2:1 to 3:1 slopes (V:H) with two intermediate berms along the hillslope and one at the sides.

Then the grid of stone masonry (in 1:4 cement: sand mortar) beams and columns with dry stone masonry infill panels was

constructed along the excavated slopes. The beams and columns are 500 mm wide and 300 mm deep. The distance between the

columns is 2 m and the vertical distance between the beams is 1.5 m (maximum). The dry stone infill saved the cost of cement and

facilitates drainage. Catch drains have been provided at the berm levels.

To date this 16 - 20 m high structure is stable. During the monsoon

ground water that has seeped from the paddy fields above can be

seen draining out from the weep holes and the dry stone panels.

Photo 9.5 Excavated slope at powerhouse

Photo 9.6 Masonry grid at powerhouse slope

9.6 Check dams and gully control

Gullies that are active or small streams where scouring of the

riverbed is prominent can be controlled by constructing check

dams. Check dams are small walls that prevent further erosion

on the watercourse and also allow deposition of bed load

upstream of it at a stable gradient. For small gullies that are

only active during the monsoon, the check dam could consist

of a simple dry stone wall. For small streams, bed erosion can

be controlled by using gabion check dams.

Gabion check dams have been used to control riverbed

scouring at the Jharkot micro-hydro scheme. The riverbed at

the Jharkot intake area had been scoured by more than 3 m at

some places and the scour depth was getting deeper. It was

felt that further scouring along the riverbed would cause total

failure of the existing gabion wall along the left bank of the

river. A series of gabion check dams was constructed at the

intake area to prevent further scouring and to facilitate the

deposition of bed load. The first check dam is shown in Fig-ure

9.4. Note that to prevent the gabion wires from being broken